Formwork are the molds constructed for the concrete casting during the construction of various structures.

In detail, the materials needed for the construction of formwork include:

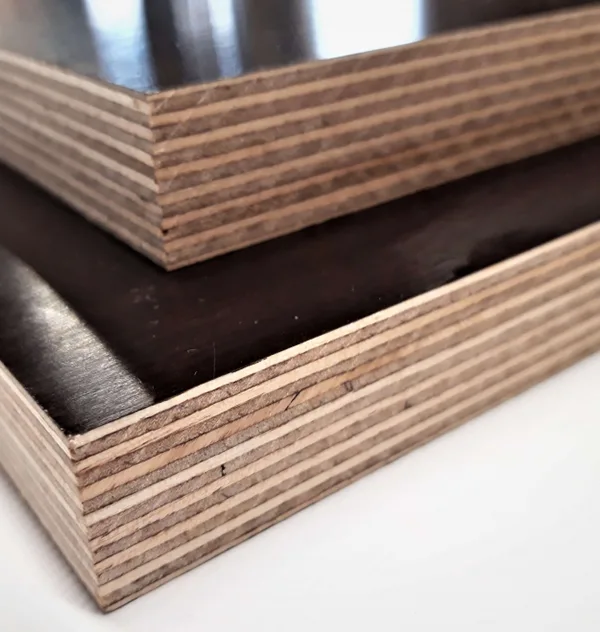

Film-faced Plywood (Shuttering)

These are plywood sheets bonded with very strong adhesives, with surfaces either veneered with phenolic film or coated with 0.5mm thick plastic material.

The advantages of a plastic-coated surface are that it doesn't stick to concrete, requires no cleaning or oiling before use, accepts nails and screws without peeling, limits material wear, and maximizes usage (up to 50 times).

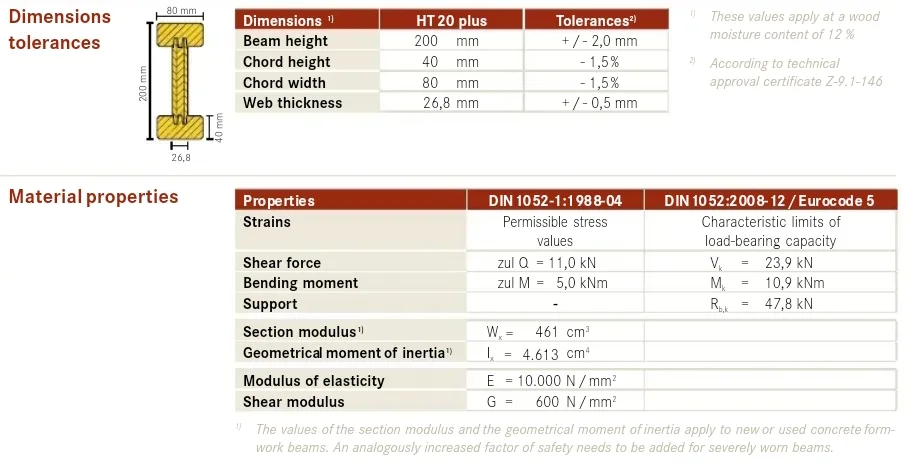

Composite Timber Beams

These are H-shaped formwork beams, with H20 being the most common (height of 20 cm).

They are made from glue laminated and compact Pine and Spruce wood, covered with a yellow resin paint to make them moisture-resistant. They offer high bending strength without warping or deterioration over time.

Lengths range from 1.50 to 6.00 meters, with 3.00 to 3.90 meters being more common.

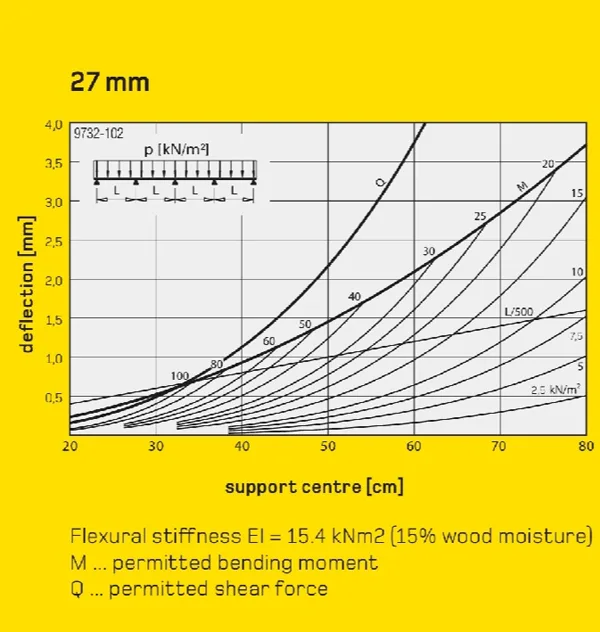

3 Ply shuttering panels (21 & 27mm thickness)

Constructed from Spruce wood and glued with phenolic adhesives, these surfaces have a width of 50 centimetres and are covered with yellow resin paint for moisture resistance. They provide high load-bearing capacity and experience minimal wear during use

Available lengths are 2.00, 2.50, and 3.00 meters.

Building Firs

Tavles - Elatakia - Maderia

Cut from excellent quality Central and Northern European Spruce wood in various dimensions, they also participate in the construction of concrete molds.

4mm Plywood

This material is typically used for shaping curved sections in formwork.